Xaloy Water Ring Pelletizer

Rr buildings recommended for you.

Xaloy water ring pelletizer. Xaloy pelletizers xaloy water ring pelletizers are suitable for processing a wide range of polymers unfilled or filled in reclaim masterbatch and general compounding. Water ring die face cutting pelletizer for compounding extrusion process duration. With the new bkg hicut and its ability to hold up to 50 more optimized blades nordson has developed a cutter hub which will elevate your pelletizing process to a whole new level. No strands to handle no water flow timing concerns.

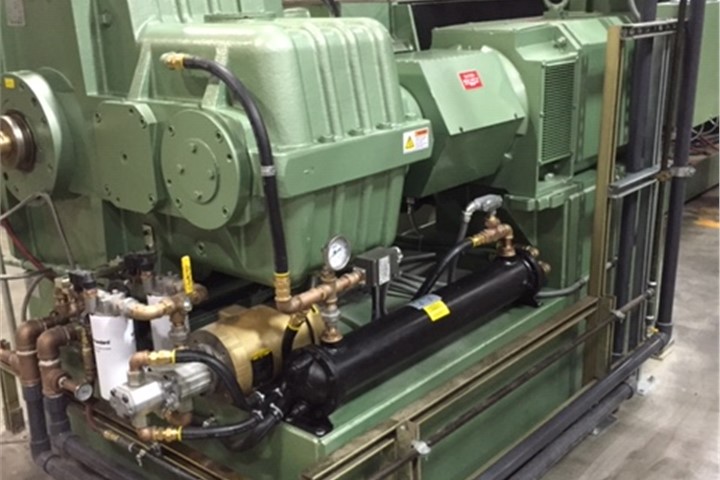

Never before seen footage duration. Used xalloy model wrp 12i water ring pelletizer. Pellets nominal rate per hour 3600 rpm maximum cutter speed 4 blade cutter head two installed 3 hp 1760 rpm cutter motor 3 hp spin dryer motor 3 hp circulation pump 135 gallons per minute water flow single temperature zone 460 3 60 in put power. Insensitive to melt flow interruptions.

Water ring pelletizing hdpe. Bkg hicut the cutter hub is the heart of every pelletizing systems and determines the output and quality of each pellet. The water ring hot die face ensures a consistent uniform pellet and is insensitive to short term polymer flow interruptions. Pictured here is gala s model 7 eac pelletizer showing the cutter hub and the cutting chamber with a bit of the downstream side of the die visible.

Nordson s bkg water ring pelletizing systems offer a modern cost effective method of pelletizing a wide range of unfilled and filled thermoplastic polymers. Mproper die sizing can cause a variety of pellet quality problems in underwater pelletizing. Bkg water ring pelletizing systems offer a modern cost effective method of pelletizing a wide range of unfilled and filled thermoplastic polymers. Xaloy s water ring pelletizer connects directly to the end of the extruder xaloy screen changer or melt pump via a short coupled adapter allowing polymer to flow horizontally from the extruder to the in line die plate.

Bkg wrp 12i in line pelletizers nordson s bkg water ring pelletizer connects directly to the end of the extruder screen changer or gear pump via a short coupled adapter allowing polymer to flow horizontally from the extruder to the in line die plate.