West System Epoxy Slow Hardener Cure Time

Higher temperatures mean faster cure speeds controlling cure time in warm and cold conditions.

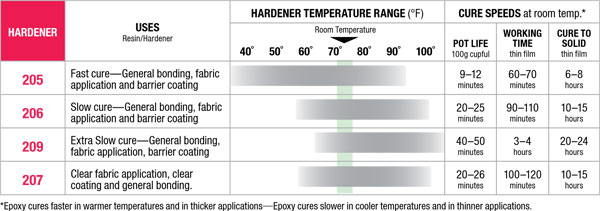

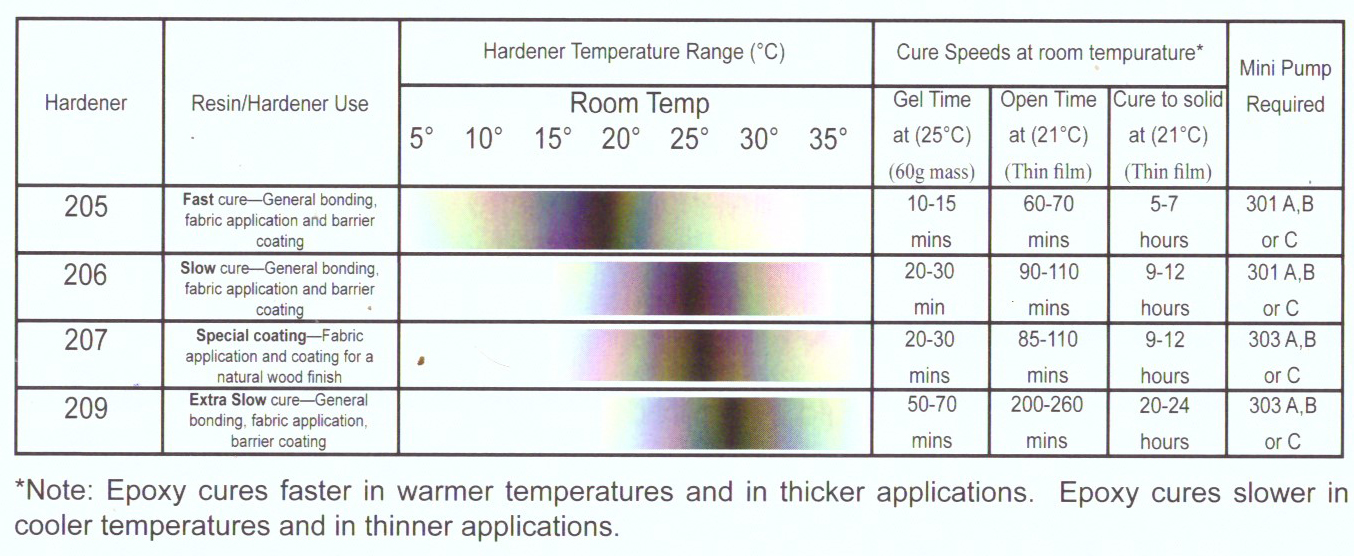

West system epoxy slow hardener cure time. 105 207 epoxy has strong physical properties so it can be used as a structural adhesive for gluing and laminating. Mix it with west system 105 resin in a five part resin to one part hardener ratio. Choose the right hardener to control the cure time of 105 epoxy resin at the temperature at which you will work. 205 fast hardener mixed at a 5 1 ratio with 105 resin results in a pot life of 9 12 minutes at 72 f with solid cure in 6 8 hours.

West system 206 slow hardener is a low viscosity epoxy curing agent for use when extended working and cure time is needed or to provide adequate working time at higher temperatures. It is useful in a majority of bonding situations and at lower temperatures. Epoxy temperature the warmer the temperature of curing epoxy the faster it cures figure 1. An epoxy s open time and overall cure time govern much of the activity of building and repairing with epoxy and hardener selection is crucial to determining open time and cure time.

209 extra slow hardener is formulated for use with west system 105 resin for general coating and bonding applications in extremely warm and or humid conditions or when extended working time is desired at room temperature. To post questions and to view pictures you will have to register by clicking here register. Each has a different cure time and an ideal temperature cure range. There are four west system hardeners.

206 slow hardener is a low viscosity epoxy curing agent for use when extended working time or a longer cure time is needed. Open time dictates the number of minutes available for mixing application smoothing shaping assembly and clamping. West system 205 fast hardener vs. At 72 degrees 206 slow hardener will have a 20 25 minute pot life.

209 extra slow hardener. Ensure you have enough working time. 205 fast hardener produces a rapid epoxy cure that develops physical properties quickly at room temperature. 205 fast hardener is a medium viscosity epoxy curing agent.

Because pot life is a measure of the cure speed of a specific contained mass volume of epoxy rather than a thin film a hardener s pot life is much shorter than its open time. Select your hardener to give you the pot life you want at the temperature and conditions in which you will work. 206 slow hardener if this is your first visit be sure to check out the faq by clicking the link above. Builders also appreciate the excellent fiberglass wet out characteristics achieved with 105 resin 207 special clear hardener yet it won t drain from vertical surfaces like the very slow curing low viscosity epoxies.

Provides approximately twice the working time of 206 slow hardener forms a clear amber colored solid with good physical properties and moisture.