Welding Power Supply Characteristics

The volt ampere characteristic of a cv power source is designed to produce almost the same voltage at no load and at rated or full load.

Welding power supply characteristics. The dip transfer characteristics depend entirely on the dynamic characteristics of the power source. With constant voltage power supply the arc voltage is established by setting the output voltage on the source. The low voltage of the arc controls spatter. They can use either direct current dc or alternating current ac and consumable or non consumable electrodes the welding region is sometimes protected by some type of inert or semi inert gas known as a shielding gas and filler.

Thus at any voltage setting current may vary from zero to an extremely high short circuit current. Plug in power mig welding power supplies are the most common and only work if you have the electricity needed to run the welder. These processes use a welding power supply to create and maintain an electric arc between an electrode and the base material to melt metals at the welding point. If the voltage of a welding arc at varying arc lengths is plotted against the welding current the curves illustrated in fig.

Such a machine is designed specifically for gas shielded metal arc welding and is not generally suitable for stick electrode welding. There are multiple arc welding processes in common use ranging from relatively simple shielded metal arc welding smaw to more complicated welding processes using inert shielding gas like gas metal arc welding gmaw or gas tungsten arc welding gtaw. A welding power supply is a device that provides or modulates an electric current to perform arc welding. The low current are used to give a quick freezing lead suitable for all positional welding and is ideal for thin sheet metal welding.

The primary functions of the power source are to produce sufficient heat to melt the joint and to generate a stable arc and metal transfer. They supply the power needed to weld but not the wire feeder or anything other welding equipment needed. Constant voltage power supply the other basic type of arc welding power supply produces a constant voltage. As the welding processes require high current 50 300a at relatively low voltage 10 50v the high voltage mains supply 230 or 400v must be reduced by a transformer.

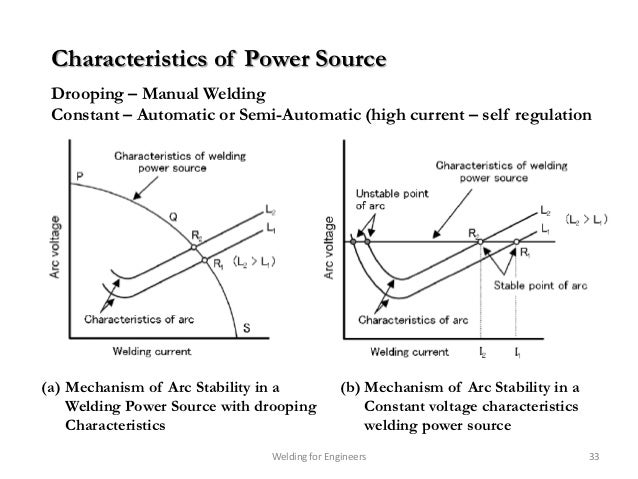

In order to understand how the requirements of the processes affect the design of the power source it is necessary to understand the interaction of the power source and the arc characteristics.