Urethane Potting Material

Epic resins has formulated a host of epoxy and urethane potting and encapsulating compounds designed to be used in microelectronic applications.

Urethane potting material. The other silicone chemistry is the condensation type which uses tin salts as catalysts. These materials are especially suitable where low temperature flexibility is required. These formulations usually offer better adhesion but are not good for potting very large masses due to unevenness of cure. Urethane withstands a wide range of temperatures and is the best choice for cold temperature applications.

They have been formulated in convenient 2 1 mix ratios and provide strong protection from moisture sea water solvents and mechanical stress. The thermoset material is usually an epoxy a urethane or a silicone potting material. Following is a table of generic uncured and cured properties for epoxy urethane and silicone potting compounds. The main constituents resin and hardener are already mixed together with no additional mixing required.

High quality microelectronics potting and encapsulating formulations and products. The low mixed viscosity of the s7475 formula allows the material to flow into intricate areas under printed circuit boards and other tight tolerance areas. Mg chemicals offers polyurethane potting compounds as a cost effective alternative to other chemistries for protecting printed circuit boards and electronic devices. Many urethane products epoxyset offers use renewable raw materials making it less harmful to the end user.

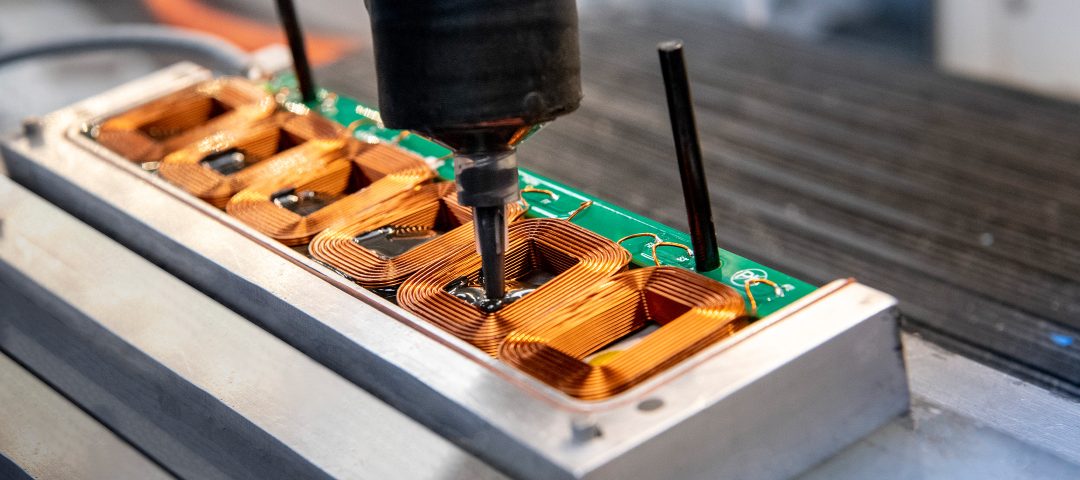

1k potting materials are a mixture of four constituents. Epoxyset urethane potting materials have low cte rates ensuring flexibility at even extremely low temperatures. Motor potting is the process of filling in all the air gaps around the coils in a motor usually the stator but sometimes also the rotor with some type of thermoset material. It is ideal for electronic applications surface mount technology and when thermal cycling resistance is a requirement.

Encase electronic assemblies in a layer of material for protection from dust moisture chemicals mechanical shock and vibration. 1k potting materials are therefore ready for use. 4 major constituents of potting material 1 k and 2 k potting one component 1k potting. Urethane modified compounds were developed by master bond to solve design manufacturing and specialty applications across a broad range of industries.

They offer a unique blend of properties for structural bonding coating sealing and potting applications. The best way to remove an electronic urethane potting compound is by using a solvent which will slowly soften the potting compound and picking away at it with a sharp tool such as a putty knife or file. S7475 2 component polyurethane compound epic s7475 is a two component polyurethane compound for potting electronic control modules ecm s and a wide variety of electronic devices.